2018 — News SP-Teploobmen

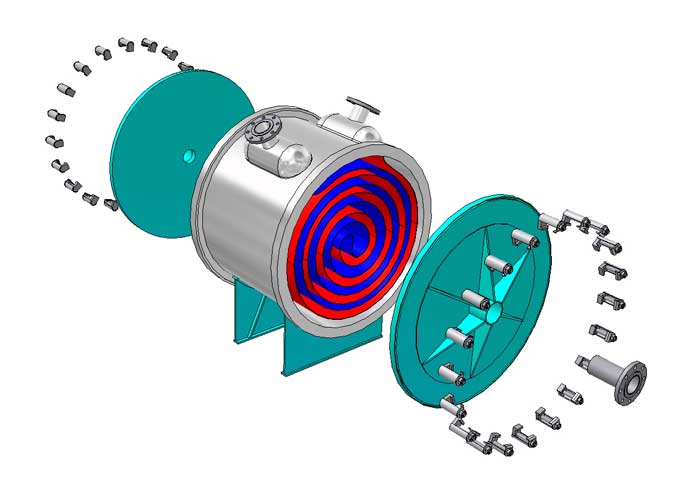

BTS Engineering Co. has developed the planning paper trial on manufacturing of Spiral Heat Exchanger of Duplex Steel Duplex SS UNS31803.

Spiral heat exchangers is made of steel the thickness of which is 2,5 mm and the width of the spiral is 2000 mm. The area of heat exchange is 160 m2 with inclusive of clogging.

Duplex S31803 – is the stainless steel with microstructure of austenite and ferrite in equal portions.

It is optimal for using in cases when high standards to mechanical durability and corrosion resistance are presupposed to be.

Horizontal spiral heat exchanger with 4400 kW of thermal output

The heat exchanger will be used for cooling oh Rhenium Sulfate ( Rhenium (VI) Sulfate).

- The area of heat exchanging is 160 m².

- The width of spiral is 2000 mm.

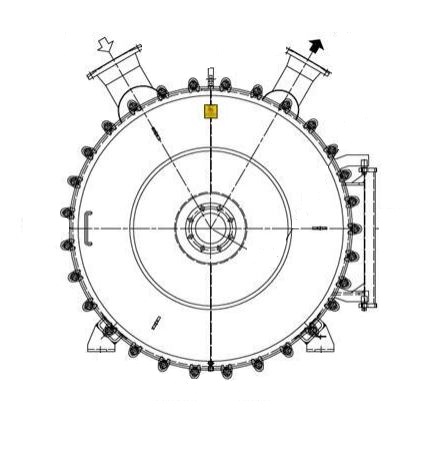

- The diameter of heat-exchange apparatus – 1500 mm.

- The routing of coolant – the counterflow .

- The heat-exchanger is designed to operate under the pressure of coolant of 6, 0 bar.

- The weight of empty heat-exchanger is 5840 kg.

The conception of spiral heat exchanger is made on spinning of 2 or 4 metal strips around the central tube, the strips are welded between each others with a help of interface prickers on ascertain distance creating 2 or 4 channels of the proportionate width. The central tube is divided on 2 parts forming the input and the out collectors. The whole construction is interposed in the cylindrical casing. The outer ends of sheets are welded along the collectors forming remained two input and output manifolds on the cheek of the casing.