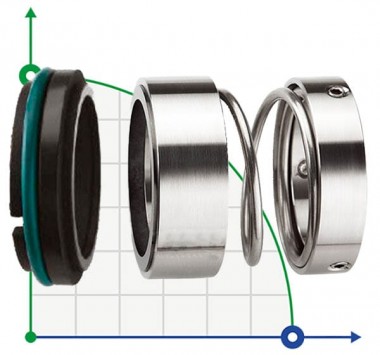

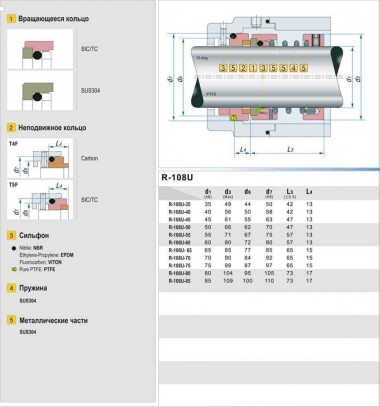

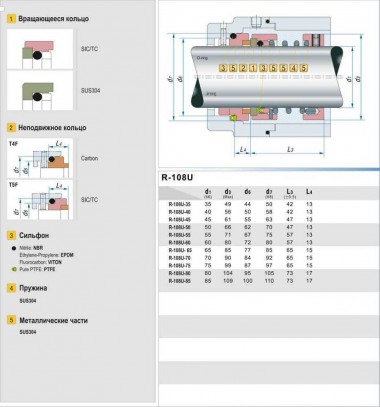

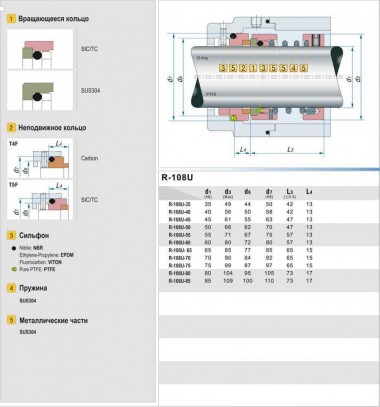

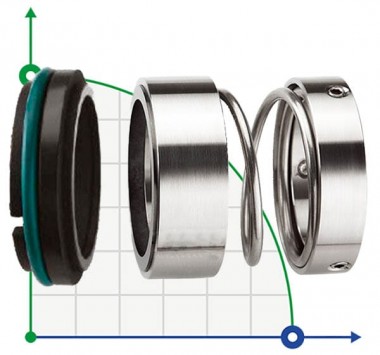

Mechanical seal R-108U

Mechanical seal R-108U

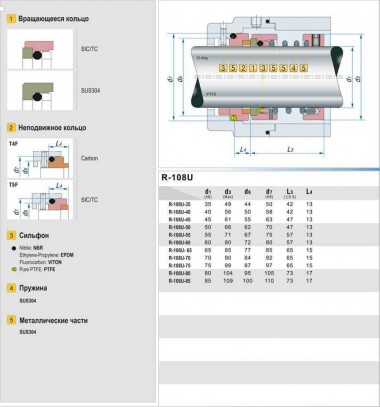

Temperature: -20 ° ~ 150 °

Pressure: ≤0.6Mpa

Speed: ≤15m / s

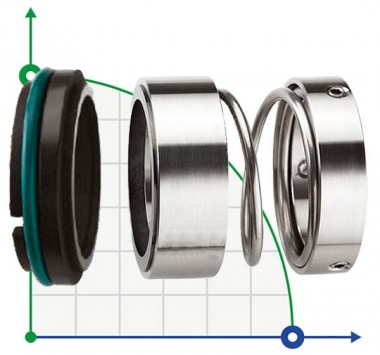

Materials

- Rotary Ring: SUS / SIC / TC.

- Stationary ring: Carbon / SIC / TC.

- Bellows: NBR / EPDM / VITON / PTFE.

- Spring: SS304.

- Metal parts: SS304.

| d1 (H6) | d3 (Max) | d6 (h8) | d7 (±0.5) | L3 | L4 |

| 35 | 49 | 44 | 50 | 42 | 13 |

| 40 | 56 | 50 | 58 | 42 | 13 |

| 45 | 61 | 55 | 63 | 47 | 13 |

| 50 | 66 | 62 | 70 | 47 | 13 |

| 55 | 71 | 67 | 75 | 57 | 13 |

| 60 | 80 | 72 | 80 | 57 | 13 |

| 65 | 85 | 77 | 85 | 65 | 15 |

| 70 | 90 | 84 | 92 | 65 | 15 |

| 75 | 99 | 87 | 97 | 65 | 15 |

| 80 | 104 | 95 | 105 | 73 | 17 |

| 85 | 109 | 100 | 110 | 73 | 17 |

Sewage pumping stations

Sewage pumping stations are designed for pumping household, drainage and industrial runoff water when transportation of liquid by gravity is impossible. CNS help to optimize and reduce the cost of materials and construction and installation work, allow you to use in pressure pipelines pipes with a smaller diameter than in somatic collectors, which in turn allows to reduce the total cost two to three times. Pumps for sewage stations The height of sewage pumping stations is set from 1.5 m up to the required by the customer. And it consists of pipes D 1200 mm - D 3000 mm, which are made of concrete of class B-30, В-35, water resistance w6 and w8, frost resistance F100, equipped with an inner polyethylene liner (PE80), which improves the waterproofing properties of structures and prolongs their service life. the optimal version of the pump station must be determined: the depth of the inlet header; necessary productivity and pressure; the volume of wastewater that enters the pumping station; type of pumped liquids; conditions of hydrogeology of construction;