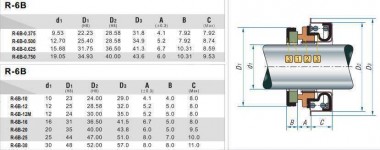

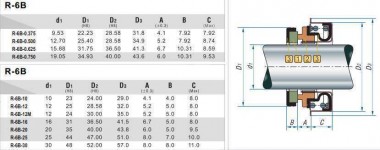

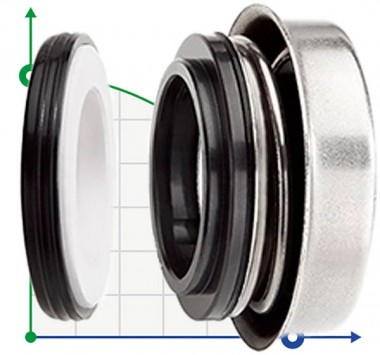

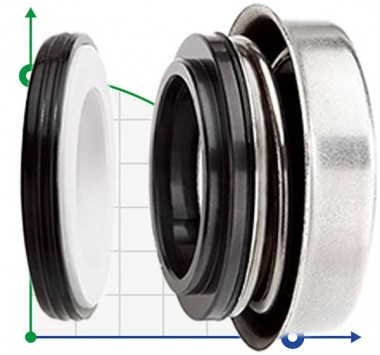

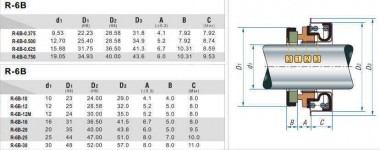

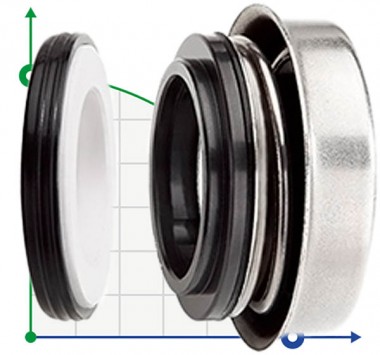

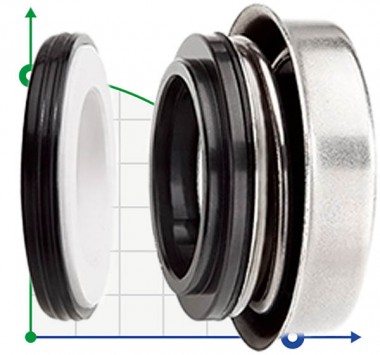

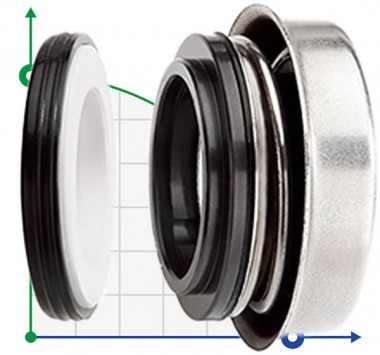

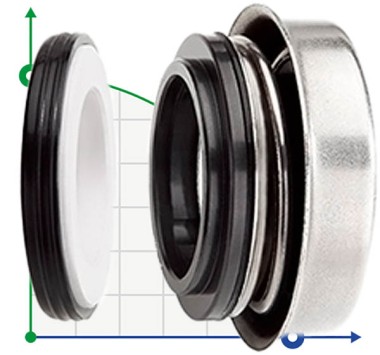

Mechanical seal R-6B

Mechanical seal R-6B

Temperature: -20 ° ~ 100 °

Pressure: ≤0.3MPa

Speed: ≤5000rpm

Materials

- Rotary Ring: Ceramic / SIC.

- Stationary ring: Ceramic /SIC.

- Bellows: NBR / HNBR.

- Spring: SS304 / SS316.

- Metal parts: SS304 / SS316.

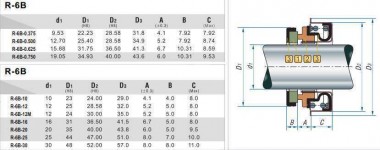

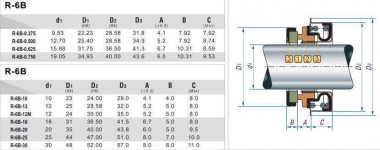

| d1 (H6) | D1 (Max) | D2 (h8) | D3 | A | B (±0.5) | C |

| 9,53 | 22,23 | 28,58 | 31,8 | 4,1 | 7,92 | 7,92 |

| 12,70 | 25,40 | 28,58 | 34,9 | 5,2 | 7,92 | 8,74 |

| 15,88 | 31,75 | 36,50 | 41,3 | 6,7 | 10,31 | 8,59 |

| 19,05 | 34,93 | 40.00 | 43,8 | 6.0 | 10,31 | 9,53 |

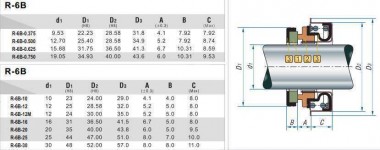

| d1 (H6) | D1 (Max) | D2 (h8) | D3 | A | B (±0.5) | C |

| 10 | 23 | 24.00 | 29.0 | 4,1 | 4 | 8.0 |

| 12 | 25 | 28,58 | 32.0 | 5,2 | 5 | 8.0 |

| 12M | 24 | 30.00 | 35.0 | 5,2 | 5 | 8.0 |

| 16 | 31 | 36,50 | 41,5 | 6,7 | 5 | 8.0 |

| 20 | 35 | 40.00 | 43,8 | 6.0 | 5 | 9,5 |

| 25 | 44 | 47.00 | 51.0 | 8.0 | 7 | 10.0 |

| 30 | 48 | 52.00 | 57.0 | 8.0 | 8 | 11.0 |

Bulk nozzle

Inert ceramic balls d 12 mm are widely used as a catalyst and support absorbent layer material in oil refining, petrochemical, Inert ceramic balls d 12 mm are widely used as a catalyst and support material of the absorbent layer in oil refining, petrochemical, gas processing industries and are characterized by incomparable impact resistance, temperature resistance and high crush strength. • Bulk density - 1380 kg /cubic meter • Voids ratio - 40% Available sizes: 1.5mm, 3mm, 6mm, 10mm, 13mm, 16mm, 19mm, 25mm, 30mm, 38mm, 50mm, 75mm. Ceramic Raschig Rings 15 mm - designed to fill the working volumes of packed columns and devices in order to increase intensity of heat and mass transfer processes in chemical, petrochemical equipment, oil refining and other industries, sewerage and water supply systems, production of ammonia and mineral fertilizers. Ceramic Raschig rings are classified as irregular nozzles and have a surface 30% larger than cylinders and balls.