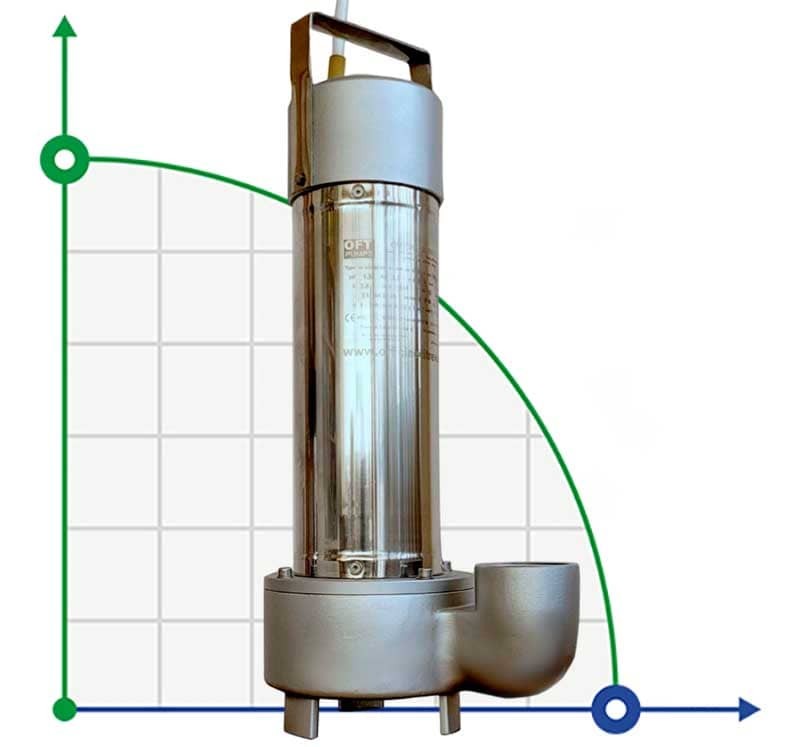

Features Drainage submersible pump BE 80 316 DERBY 150, 380V

PumpType

submersible drainage and fecal

Material

AISI 316 stainless steel

Drive Type

electric

Max. head, m

13.1

Installation Type

vertical

Description

Applications of the OFT Pumps BE 80 316 DERBY series: pumping contaminated liquid, collecting leachate, lifting liquid from wells and tanks contaminated even with hydrocarbons and sewage, pumping condensate wells, pumping contaminated wastewater. The pumps must not be installed in potentially explosive atmospheres.

Features: open impeller made of AISI 316 SS stainless steel to avoid clogging with liquid, landfill leachate and other small solids. The seal is made of fluorine rubber (Viton). The motor shaft and housing are made of AISI 316 stainless steel. Electric pumps are produced with a 5 m long ID 4G1.5 electric cable included.

Motor: 2-pole asynchronous motor, 50 Hz, 2850 rpm. Insulation class F. Protection IP68. The motor is cooled by a non-toxic, environmentally friendly liquid. The motor is protected by thermal switches resistant to temperatures up to 80°C.

Operating conditions: The pump must not be run dry. The pump casing must always be completely immersed in the liquid. The temperature of the pumped liquid should be at least 0°C and maximum 80°C. Vertical operating position. Maximum number of starts per hour: 20.

Accessories: control panel, level controller, BE electronic level sensor, ID 4G1, 5 round cable.