Designing a rectified ethyl alcohol plant 300-30000 dal / day from starch-containing raw materials

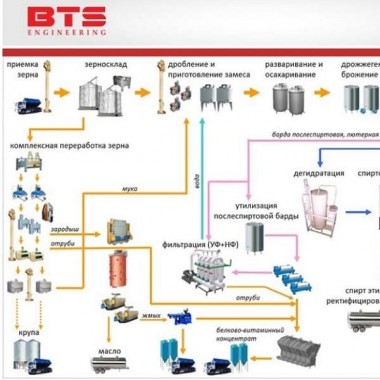

As a raw material for the production of rectified ethanol can act corn, wheat, and other types of starch raw materials.

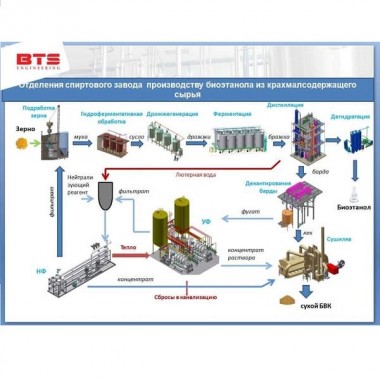

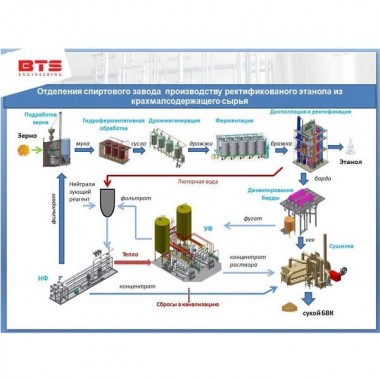

The production technology is shown in the figure

Design of a plant for the production of rectified ethanol can be divided into the following sequential stages:

- Pre-design work

- Project development

- Expertise of the project

- Obtaining permission to start construction

- Construction

- Commissioning

- Manufacturing certification

- Output

Pre-design work includes

- Development of technical specifications (customer + designer)

- Obtaining urban planning conditions and restrictions on plot;

- Obtaining technical conditions for connection energy carriers.

- Receiving technical specifications for the production of rectified ethanol (purchase)

- Development of factory regulations for the release of rectified ethanol

Project development

The design of the object of the class of consequences CC3 is carried out in three stages

- Feasibility study stage (feasibility study)

- Stage P (project)

- Stage P (working documentation)

Expertise of the project

Carried out in a specialized organization that has permission for the examination of projects with a class of consequences CC3. On examination is submitted to stage P. Obtaining permission to start construction takes place in IGASN (Inspection of the State Architectural and Construction supervision) after receiving a positive opinion expertise.

Sort by:

Sale