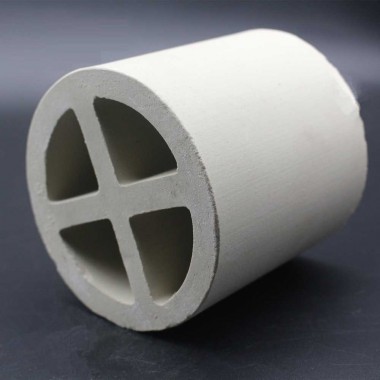

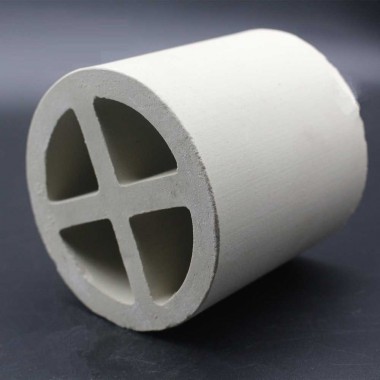

Cross-Partition Ring

Cross-Partition Ring

Ceramic Cross Partition Ring. Ceramic Cross Partition Ring, its shape is in the middle of Ceramic Raschig Ring adds cross partition, thus expanding the specific surface area, increasing the compressive strength, reducing the pressure drop, reducing channeling and wall flow, and strengthening the mass transfer efficiency. Xintao Ceramic Cross Partition Ring, can resist to corrosion of various inorganic acids, organic acids and organic solvents except hydrofluoric acid, and can be used in high or low temperature conditions. Typical Application: Be used in the drying columns, absorbing columns, cooling towers, scrubbing towers and actifier columns in chemical industry, metallurgy industry, coal gas industry, oxygen producing industry, etc.

| SiO2 + Al2O3 | > 92% | CaO | < 1.0% |

| SiO2 | > 76% | MgO | < 0.5% |

| Al2O3 | > 17% | K2O + Na2O | < 3.5% |

| Fe2O3 | < 1.0% | Other | < 1% |

| Water absorption | < 0.5% | Moh's hardness | > 6.5 scale |

| Porosity | < 1% | Acid resistance | > 99.6% |

| Specific gravity | 2.3–2.40 g/cm3 | Alkali resistance | > 85% |

| Max. operation temperature | 1200 °C | ||

| Size (mm) |

Thickness (mm) |

Surface area (m2/m3) |

Voidage (%) |

Bulk Quantity (pcs/m3) |

Bulk density (kg/m3) |

|---|---|---|---|---|---|

| 50 | 5.5 | 150 | 53 | 6400 | 800 |

| 80 | 8 | 120 | 54 | 1960 | 916 |

| 100 | 10 | 110 | 53 | 1000 | 930 |

| 150 | 15 | 60 | 58 | 296 | 960 |