Processing of distillery stillage

Subsidiary enterprise "BTS-ENGINEERING" carries out construction of offices for the processing of distillery stillage.

At the stage of distilling alcohol, the main waste of its production is formed – distillery dreg. For existing alcohol production Subsidiary Enterprise "BTS-ENGINEERING" offers the construction of plants for the processing of distillery stillage.1

Distillery stillage is processed to produce DDGS:

Distillery stillage is processed to produce DDGS:

- DDGS (dried distillers grains with solvents ) – can be used as a high-quality animal feed.

Advanced technologies used in the construction of post-alcohol bard processing units ensure high quality of the resulting dry enriched distiller's wash (DDGS) at a low level of energy consumption.

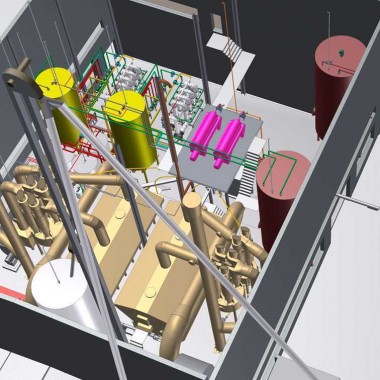

Department of complex processing of dried distillers – 3D model.

Use of membrane technologies for separation and thickening of process waste

- The scheme uses existing membrane installations with replacement ceramic membranes.

- The membrane technology reduces the consumption of "fresh" artesian water for the technology and reduces the discharge of process wastewater.

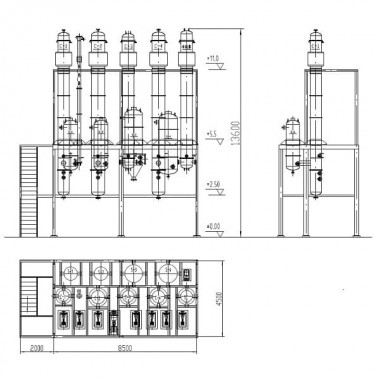

Projects for distillery stillage processing.

The production of DDGS.

- Development and implementation of DDGS production scheme from distillery stillage

- Development, laboratory research of filtration technologies in the production of ethanol, bioethanol, DDGS from distillery stillage

- Design of a laboratory ultrafiltration unit

- Debugging technologies on a laboratory installation

- Design and engineering of a pilot ultrafiltration plant

- Installation, start-up and operation of a pilot plant

- Development and implementation of integrated grain processing scheme

- Development and implementation of an automated process control system (automated process control system) using the original software product

Sale