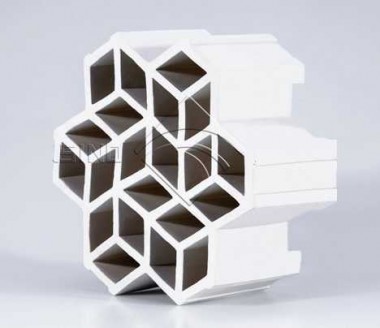

Seven Ring

Seven Ring

Due to the fact that the flat ceramic corrugated nozzle is very heavy and therefore easy to break, in the late 1980s, scientists decided not to use clay and make a lighter porcelain packing. This packing is widely used in the processes of chemical cooking, desulfurization, washing of benzene, drying of naphthalene, ammonia and sulfuric acid, mineral fertilizers, hot water supply, saturation columns, power stations, cooling towers, absorbers, etc. The packing is characterized by a wide temperature range, low specific gravity, low stability, high mass transfer coefficient, good absorption capacity, high corrosion resistance, long service life.

| Title | Size, mm | Specific surface area, m2/m3 | Pore volume, % | The number of PCs/m3 | Density, kg / m3 | Current quantity, PCs / m3 |

| Seven Ring | 220±0.5 | 65 | 118 | 85 | 200 | 320 |

| Packing of seven rings and a body ring | 220±0.5 | 65 | 128 | 75 | 200 | 420 |

| Diamond-shaped ring | 220±0.5 | 65 | 135 | 72 | 200 | 420 |

| Diamond-shaped ring with body ring | 220±0.5 | 65 | 132 | 75 | 200 | 380 |

| Ring with rotary mechanism | 220±0.5 | 65 | 148 | 73 | 200 | 450 |

| The toothed ring | 220±0.5 | 65 | 125 | 72 | 200 | 480 |

Sort by:

Sale