Spiral Heat Exchangers

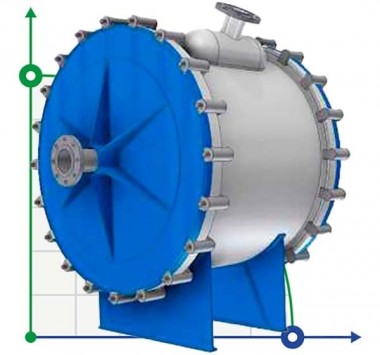

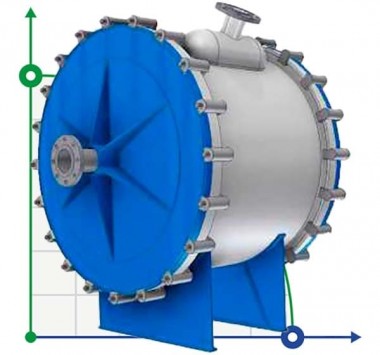

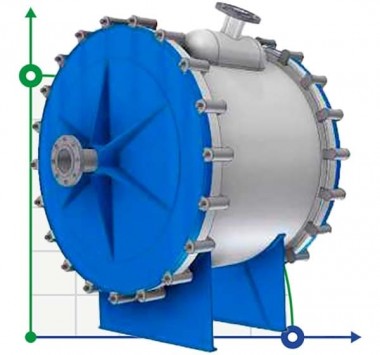

Spiral heat exchanger – types of heat exchangers for use in technological processes in the production of alcohol, bioethanol, recuperative spiral heat exchangers for heat stations, organization of cold in the recycling water supply of enterprises. Our company offers two types of heat exchangers – collapsible, when the covers on the spiral side can be opened for inspection, flushing. Welded spiral heat exchangers – when the sheets are welded. Combined spiral heat exchangers-when one side of the heat exchanger is collapsible, the cover of the spiral heat exchanger is removed, and the other side is welded.

Welded spiral heat exchangers have an advantage over collapsible ones in that they can withstand higher fluid pressure and have more structural rigidity. Spiral heat exchangers do not need to be demountable at all technological cycles, since the organization of technological flushing with the use of caustic and cleaning solutions does not require their disassembly.

Our engineers can design a SIP sink for process equipment according to the customer's requirements.

A spiral heat exchanger is a device for transferring heat energy from one heat carrier to another. As a heat carrier, gaseous, liquid or vapor-liquid media can be used.

The company "BTS-ENGINEERING" is engaged in projecting and calculating spiral heat exchangers for technological processes.

There are two types of spiral heat exchangers:

- collapsible heat exchangers;

- welded heat exchangers.

Welded Heat Exchangers

Welded heat exchangers are compact heat exchangers for application at extremely high temperature, pressure of units, parameters of which do not allow seal using. They feature high efficiency, small dimensions and do not require much maintenance.

Welded heat exchangers are manufactured of different materials. Design quality of welded heat exchangers complies with the highest requirements.

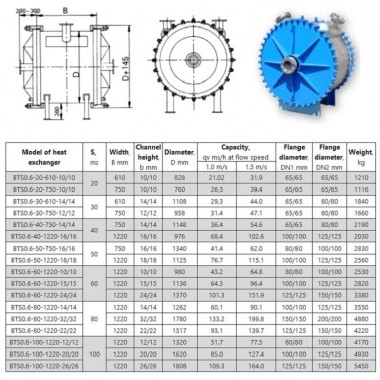

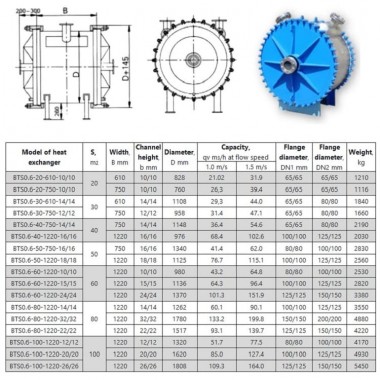

Spiral Heat Exchangers

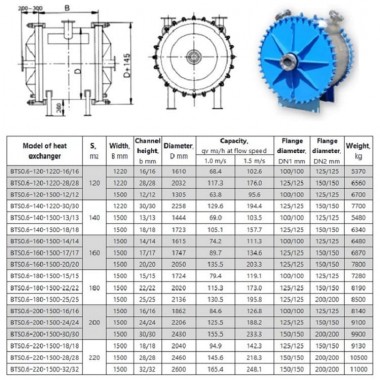

Technical information

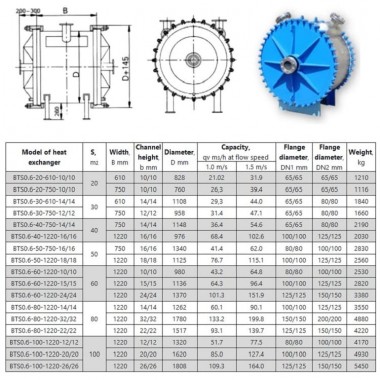

| Model of heat exchanger | S, m2 | Width, B mm | Channel height, b mm | Diameter, D mm | Capacity, qv m3/h at flow speed | Flange diameter, DN1 mm | Flange diameter, DN2 mm | Weight, kg | |

| 1.0 m/s | 1.5 m/s | ||||||||

| BTS0.6-20-610-10/10 | 20 | 610 | 10/10 | 828 | 21.2 | 31.9 | 65/65 | 65/65 | 1210 |

| BTS0.6-20-750-10/10 | 750 | 10/10 | 760 | 26.3 | 39.4 | 65/65 | 65/65 | 1116 | |

| BTS0.6-30-610-14/14 | 30 | 610 | 14/14 | 1108 | 29.3 | 44.0 | 65/65 | 80/80 | 1840 |

| BTS0.6-30-750-12/12 | 750 | 12/12 | 958 | 31.4 | 47.1 | 65/65 | 80/80 | 1660 | |

| BTS0.6-40-750-14/14 | 40 | 750 | 14/14 | 1148 | 36.4 | 54.6 | 65/65 | 80/80 | 2190 |

| BTS0.6-40-1220-16/16 | 1220 | 16/16 | 976 | 68.4 | 102.6 | 100/100 | 125/125 | 2030 | |

| BTS0.6-50-750-16/16 | 50 | 750 | 16/16 | 1340 | 41.4 | 62.0 | 80/80 | 100/100 | 2830 |

| BTS0.6-50-1220-18/18 | 1220 | 18/18 | 1125 | 76.7 | 115.1 | 100/100 | 125/125 | 2560 | |

| BTS0.6-60-1220-10/10 | 60 | 1220 | 10/10 | 980 | 43.2 | 64.8 | 80/80 | 100/100 | 2530 |

| BTS0.6-60-1220-15/15 | 1220 | 15/15 | 1136 | 64.3 | 96.4 | 100/100 | 125/125 | 2820 | |

| BTS0.6-60-1220-24/24 | 1220 | 24/24 | 1370 | 101.3 | 151.9 | 125/125 | 150/150 | 3380 | |

| BTS0.6-80-1220-14/14 | 80 | 1220 | 14/14 | 1262 | 60.1 | 90.1 | 100/100 | 125/125 | 3550 |

| BTS0.6-80-1220-32/32 | 1220 | 32/32 | 1780 | 133.2 | 199.8 | 150/150 | 200/200 | 4880 | |

| BTS0.6-80-1220-22/22 | 1220 | 22/22 | 1517 | 93.1 | 139.7 | 125/125 | 150/150 | 4220 | |

| BTS0.6-100-1220-12/12 | 100 | 1220 | 12/12 | 1320 | 51.7 | 77.5 | 80/80 | 100/100 | 4170 |

| BTS0.6-100-1220-20/20 | 1220 | 20/20 | 1620 | 85.0 | 127.4 | 100/100 | 125/125 | 4930 | |

| BTS0.6-100-1220-26/26 | 1220 | 26/26 | 1808 | 109.3 | 164.0 | 125/125 | 150/150 | 5450 | |

| BTS0.6-120-1220-16/16 | 120 | 1220 | 16/16 | 1610 | 68.4 | 102.6 | 100/100 | 125/125 | 5370 |

| BTS0.6-120-1220-28/28 | 1220 | 28/28 | 2032 | 117.3 | 176.0 | 125/125 | 150/150 | 6560 | |

| BTS0.6-120-1500-12/12 | 1500 | 12/12 | 1305 | 63.8 | 95.6 | 100/100 | 125/125 | 6700 | |

| BTS0.6-140-1220-30/30 | 140 | 1220 | 30/30 | 2258 | 129.6 | 194.4 | 125/125 | 150/150 | 7700 |

| BTS0.6-140-1500-13/13 | 1500 | 13/13 | 1444 | 69.0 | 103.5 | 100/100 | 125/125 | 5480 | |

| BTS0.6-140-1500-18/18 | 1500 | 18/18 | 1723 | 105.1 | 157.7 | 125/125 | 150/150 | 6340 | |

| BTS0.6-160-1500-14/14 | 160 | 1500 | 14/14 | 1615 | 74.2 | 111.3 | 100/100 | 125/125 | 6480 |

| BTS0.6-160-1500-17/17 | 1500 | 17/17 | 1747 | 89.7 | 134.6 | 125/125 | 150/150 | 6870 | |

| BTS0.6-160-1500-20/20 | 1500 | 20/20 | 2050 | 135.5 | 203.3 | 125/125 | 150/150 | 7800 | |

| BTS0.6-180-1500-15/15 | 180 | 1500 | 15/15 | 1724 | 79.4 | 119.1 | 100/100 | 125/125 | 7280 |

| BTS0.6-180-1500-22/22 | 1500 | 22/22 | 2020 | 115.3 | 173.0 | 125/125 | 150/150 | 8190 | |

| BTS0.6-180-1500-25/25 | 1500 | 25/25 | 2136 | 130.5 | 195.8 | 125/125 | 200/200 | 8500 | |

| BTS0.6-200-1500-16/16 | 200 | 1500 | 16/16 | 1862 | 84.6 | 126.8 | 100/100 | 125/125 | 8140 |

| BTS0.6-200-1500-24/24 | 1500 | 24/24 | 2206 | 125.5 | 188.2 | 125/125 | 150/150 | 9100 | |

| BTS0.6-200-1500-30/30 | 1500 | 30/30 | 2430 | 155.5 | 233.3 | 150/150 | 200/200 | 9900 | |

| BTS0.6-220-1500-18/18 | 220 | 1500 | 18/18 | 2040 | 94.9 | 142.3 | 125/125 | 150/150 | 9130 |

| BTS0.6-220-1500-28/28 | 1500 | 28/28 | 2460 | 145.6 | 218.3 | 150/150 | 200/200 | 10500 | |

| BTS0.6-220-1500-32/32 | 1500 | 32/32 | 2600 | 165.4 | 248.1 | 150/150 | 200/200 | 11000 | |