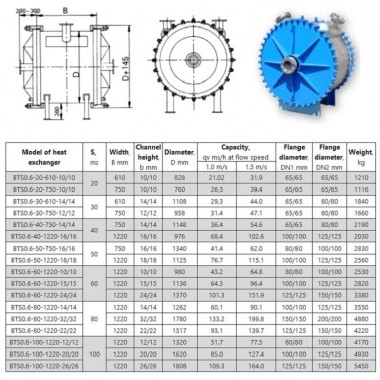

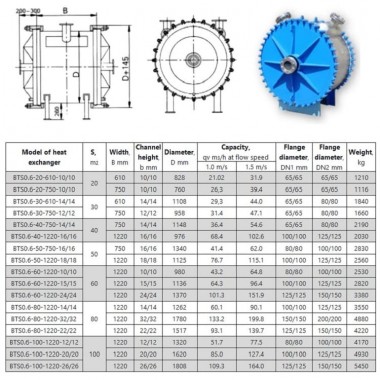

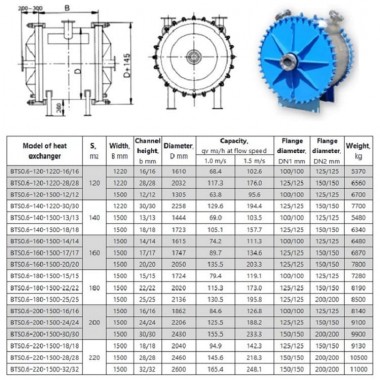

Diagrams of using a spiral heat exchanger

of spiral heat exchanger in distillation industry

Recovery of distillery dreg heat for heating water for mash tank

Distillery dreg from distillation column is pumped into the spiral heat exchanger where it is cooled down, then it is transferred into distillery dreg tanks; water getting into the spiral heat exchanger is heated up and then enters the mash tank.

This system has been applied at the State Owned Enterprise "Zalozetsky Alcohol Plant".

Heating fermented wash before distillation

Fermented mash is pumped into the spiral heat exchanger where it is heated up and then transferred into the wash heater of distillation column. Mash from the fermenter is pumped to the spiral heat exchanger where it is cooled down, after that it is transferred to the fermenter tank.

This system has been applied at the State Owned Enterprises "Stadnitsky Alcohol Plant" and "Zalozetsky Alcohol Plant".

Mash cooling in the recycling water supply system

Mash is pumped from the fermenter into the spiral heat exchanger where it is cooled and then is pumped into the fermenter. Water from the cooling tower is pumped into the spiral heat exchanger where it is heated up, after that it goes back to the cooling tower, where it is cooled down.

This system has been applied at the State Owned Enterprise "Lutsky Alcohol Plant".

Cooling fermentation tanks by spiral heat exchangers

Fermenting wort is pumped from the alcohol fermenter into the spiral heat exchanger where it is cooled down, then it goes back into the same fermenter. Water getting into the spiral heat exchanger, is heated up and then pumped into the water tank.

This system has been applied at the State Owned Enterprise "Marylivsky Alcohol Plant".

Diagram of series connection of heat exchangers for wort cooling