A questionnaire for the selection of a spiral heat exchanger

Making spiral heat exchangers

BTS-ENGINEERING Company Designs and manufactures spiral heat exchangers for technological processes of enterprises. Heat exchangers for difficult media: spiral heat exchanger for alcohol filling, spiral heat exchanger for wort cooling, recuperative spiral mix-wort heat exchanger, mash heating heat exchanger, spiral heat exchanger for fermentation tank, spiral stillage-batch heat exchanger (batch water). Spiral heat exchanger for the production of sunflower, rapeseed oils - after the brazier, for cooling with circulating water from a temperature of 110-120 C to 40 C. A spiral heat exchanger for heat pump, spiral biogas heat exchanger. Spiral heat exchanger for pulp, chemistry, food.

Spiral heat exchangers are widely used in various industries due to the advantages before other types of heat exchangers.

- spiral heat exchangers for the chemical industry

- spiral heat exchangers for utilities

- spiral heat exchangers for the food industry

- spiral heat exchangers for distilleries

Spiral heat exchangers are used as condensers, evaporators, as well as for cooling and heating

liquids, gases and steam-gas mixtures.

The distillation columns can be configured with spiral heat exchangers as reflux condensers.

Spiral heat exchangers are especially effective for handling highly viscous liquids, since the problem is eliminated

distribution of such liquid in pipes, as well as in the treatment of sludge and liquids containing fibrous materials and

inclusion.

ADVANTAGES OF THE SPIRAL HEAT EXCHANGER

- The possibility of using spiral heat exchangers with "problematic" media, such as strong contaminated liquids, aggressive and highly viscous media, etc.

- High efficiency of spiral heat exchangers over the entire load range

- Low pressure loss through the channels of spiral heat exchangers

- Compactness of the spiral heat exchanger, thus saving useful space

- Easy cleaning of spiral scale heat exchangers by mechanical or chemical flushing methods

- A wide range of flow types and channel types in spiral heat exchangers

Reducing the operating costs of spiral heat exchangers for shutdowns, since cleaning is carried out much less frequently and

lighter than other types of heat exchangers, shell and tube, plate and others.

Spiral heat exchangers are suitable for cooling vegetable oils, suspensions, ingredients with the inclusion of dry

substances, particles of grain, malt, etc.

At an alcohol plant, a bioethanol plant, where the production of alcohol from starch-containing raw materials uses the following

technological cycle:

- preparation, cleaning and crushing of grain.

- mixing with hot water that comes out of the spiral heat exchanger heated to a temperature of 80-90 degrees. Water is heated on a spiral heat exchanger, in technology it is called a recuperative spiral heat exchanger brewing compartment.

- spiral heat exchanger for cooling the wort after HDFO (hydro-enzymatic treatment) cooling the wort with inclusion of 20-25% dry substances from a temperature of 90 ° C to temperatures of 60 ° C (in the case of using a desiccant) or up to a temperature of 32-35 ° C (in circuits that are not used dehydrator in technology).

Spiral heat exchangers have proven themselves very well instead of

built-in coils in fermentation tanks (built-in coils-heat exchangers inside the fermentation tank) are poorly cleaned from

for the structural features of the placement and therefore leads to microbiological contamination of the wash. And rendered

the spiral heat exchanger for cooling the wash is well washed. When washing the fermentation tank, pump water and

through a spiral heat exchanger.

Spiral heat exchangers have proven themselves well in systems

recycling water supply using natural sources that act as a refrigerant.

Spiral heat exchangers or spiral heat exchanger stands on the primary circuit - pond, river, storage. The spiral heat exchanger is not afraid of BIOLOGICAL AND MECHANICAL contamination in the circulating water, the reason

which can be entered.

Heat exchangers with a removable cover are easy to clean from dirt and can

be used for heat transfer fluids with solid inclusions or biological deposits, thereby blocking the passage,

as in plate heat exchangers. Heat exchangers with a removable cover are easy to clean from dirt and can

used for heat transfer fluids with solid inclusions.

Constructional features of the manufacture of spiral heat exchangers.

Constructional features of the manufacture of spiral heat exchangers.

In order to strengthen the structure of the spiral heat exchanger, spacers are used between the sheets of the spiral

heat exchanger -

pins. The pins between the sheets of the spiral heat exchanger are made of a material similar to that of the sheet of spiral

heat exchangers. Fix the pins by welding to the sheet of the spiral heat exchanger.

spacers between the sheets of the spiral heat exchanger - pins

Spiral heat exchangers have a number of advantages over other types: plate heat exchanger, shell-and-tube

heat exchanger.

The main advantage is the ability to use spiral heat exchangers for pumping liquids and mixtures,

which include solid

particles commensurate with the height between the turns of the spiral. If, for example, the height between the sheets of a spiral heat exchanger

14 mm, then the size of inclusions in the liquid may well reach 10-12 mm.

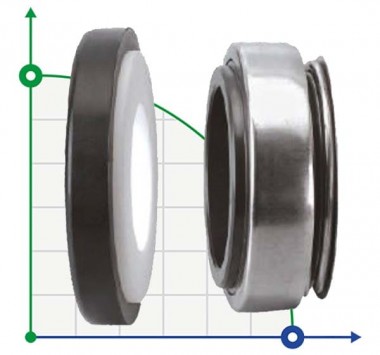

Types of spiral heat exchangers:

vertical spiral heat exchangers

horizontal spiral heat exchangers

Spiral heat exchangers - equipment widely used and used in the world industry, which is explained by a number of their important advantages over other types of heat exchangers. Spiral heat exchangers can be made from any roll material that is cold worked and welding. Heat exchangers are compact, their design allows for full counterflow.

Self-cleaning effect is done spiral heat exchangers universal equipment - they applicable as in the work with liquid inhomogeneous media, prone to the formation of deposits on heat transfer surfaces, and in the presence of condensation of steam or gas in high vacuum conditions.

The cross-sectional area of the channels along the entire length remains unchanged, and the flow does not have sharp changes in direction, due to which the surface contamination of spiral heat exchangers is less than that of other types of heat exchangers.

Characteristics of spiral heat exchangers

Advantages of spiral heat exchangers:

- High heat transfer coefficient reaching 3820 kcal /m2 × h ×oWith that 2-3 times higher than that of tubular heat exchangers.

- Reliable design, due to the sealing of each of the two passages, counter flows do not mix.

- They take up a much smaller area compared to tubular heat exchangers.

- Ability to work with media containing pulp, fibers, solid sediment (up to 20%), as well as viscous environments.

- They are characterized by compactness, low hydraulic resistance and significant intensity heat transfer at increased speeds of heat carriers.

- Ease of access to internal surfaces and channels. Convenient and accessible for maintenance thanks to removable covers. It is enough to remove the covers and access to the entire surface of the channel is open for inspection and cleaning.

- The ability to work with environments with temperatures above 200-300 ° C, which is very important in chemical industry.

| Heat exchanger model | S м2 | Width, B mm | Channel height, b mm | Diameter, D mm | Performance, qv m3/h at flow speed | Flanza diameter, DN1 mm | Flanza diameter, DN2 mm | Weight, kg | |

| 1.0 м/с | 1.5 м/с | ||||||||

| BTS0.6-20-610-10/10 | 20 | 610 | 10/10 | 828 | 21.2 | 31.9 | 65/65 | 65/65 | 1210 |

| BTS0.6-20-750-10/10 | 750 | 10/10 | 760 | 26.3 | 39.4 | 65/65 | 65/65 | 1116 | |

| BTS0.6-30-610-14/14 | 30 | 610 | 14/14 | 1108 | 29.3 | 44.0 | 65/65 | 80/80 | 1840 |

| BTS0.6-30-750-12/12 | 750 | 12/12 | 958 | 31.4 | 47.1 | 65/65 | 80/80 | 1660 | |

| BTS0.6-40-750-14/14 | 40 | 750 | 14/14 | 1148 | 36.4 | 54.6 | 65/65 | 80/80 | 2190 |

| BTS0.6-40-1220-16/16 | 1220 | 16/16 | 976 | 68.4 | 102.6 | 100/100 | 125/125 | 2030 | |

| BTS0.6-50-750-16/16 | 50 | 750 | 16/16 | 1340 | 41.4 | 62.0 | 80/80 | 100/100 | 2830 |

| BTS0.6-50-1220-18/18 | 1220 | 18/18 | 1125 | 76.7 | 115.1 | 100/100 | 125/125 | 2560 | |

| BTS0.6-60-1220-10/10 | 60 | 1220 | 10/10 | 980 | 43.2 | 64.8 | 80/80 | 100/100 | 2530 |

| BTS0.6-60-1220-15/15 | 1220 | 15/15 | 1136 | 64.3 | 96.4 | 100/100 | 125/125 | 2820 | |

| BTS0.6-60-1220-24/24 | 1220 | 24/24 | 1370 | 101.3 | 151.9 | 125/125 | 150/150 | 3380 | |

| BTS0.6-80-1220-14/14 | 80 | 1220 | 14/14 | 1262 | 60.1 | 90.1 | 100/100 | 125/125 | 3550 |

| BTS0.6-80-1220-32/32 | 1220 | 32/32 | 1780 | 133.2 | 199.8 | 150/150 | 200/200 | 4880 | |

| BTS0.6-80-1220-22/22 | 1220 | 22/22 | 1517 | 93.1 | 139.7 | 125/125 | 150/150 | 4220 | |

| BTS0.6-100-1220-12/12 | 100 | 1220 | 12/12 | 1320 | 51.7 | 77.5 | 80/80 | 100/100 | 4170 |

| BTS0.6-100-1220-20/20 | 1220 | 20/20 | 1620 | 85.0 | 127.4 | 100/100 | 125/125 | 4930 | |

| BTS0.6-100-1220-26/26 | 1220 | 26/26 | 1808 | 109.3 | 164.0 | 125/125 | 150/150 | 5450 | |

| BTS0.6-120-1220-16/16 | 120 | 1220 | 16/16 | 1610 | 68.4 | 102.6 | 100/100 | 125/125 | 5370 |

| BTS0.6-120-1220-28/28 | 1220 | 28/28 | 2032 | 117.3 | 176.0 | 125/125 | 150/150 | 6560 | |

| BTS0.6-120-1500-12/12 | 1500 | 12/12 | 1305 | 63.8 | 95.6 | 100/100 | 125/125 | 6700 | |

| BTS0.6-140-1220-30/30 | 140 | 1220 | 30/30 | 2258 | 129.6 | 194.4 | 125/125 | 150/150 | 7700 |

| BTS0.6-140-1500-13/13 | 1500 | 13/13 | 1444 | 69.0 | 103.5 | 100/100 | 125/125 | 5480 | |

| BTS0.6-140-1500-18/18 | 1500 | 18/18 | 1723 | 105.1 | 157.7 | 125/125 | 150/150 | 6340 | |

| BTS0.6-160-1500-14/14 | 160 | 1500 | 14/14 | 1615 | 74.2 | 111.3 | 100/100 | 125/125 | 6480 |

| BTS0.6-160-1500-17/17 | 1500 | 17/17 | 1747 | 89.7 | 134.6 | 125/125 | 150/150 | 6870 | |

| BTS0.6-160-1500-20/20 | 1500 | 20/20 | 2050 | 135.5 | 203.3 | 125/125 | 150/150 | 7800 | |

| BTS0.6-180-1500-15/15 | 180 | 1500 | 15/15 | 1724 | 79.4 | 119.1 | 100/100 | 125/125 | 7280 |

| BTS0.6-180-1500-22/22 | 1500 | 22/22 | 2020 | 115.3 | 173.0 | 125/125 | 150/150 | 8190 | |

| BTS0.6-180-1500-25/25 | 1500 | 25/25 | 2136 | 130.5 | 195.8 | 125/125 | 200/200 | 8500 | |

| BTS0.6-200-1500-16/16 | 200 | 1500 | 16/16 | 1862 | 84.6 | 126.8 | 100/100 | 125/125 | 8140 |

| BTS0.6-200-1500-24/24 | 1500 | 24/24 | 2206 | 125.5 | 188.2 | 125/125 | 150/150 | 9100 | |

| BTS0.6-200-1500-30/30 | 1500 | 30/30 | 2430 | 155.5 | 233.3 | 150/150 | 200/200 | 9900 | |

| BTS0.6-220-1500-18/18 | 220 | 1500 | 18/18 | 2040 | 94.9 | 142.3 | 125/125 | 150/150 | 9130 |

| BTS0.6-220-1500-28/28 | 1500 | 28/28 | 2460 | 145.6 | 218.3 | 150/150 | 200/200 | 10500 | |

| BTS0.6-220-1500-32/32 | 1500 | 32/32 | 2600 | 165.4 | 248.1 | 150/150 | 200/200 | 11000 | |

Applications:

- Refining (Heavy oils, washing oils)

- Chemical industry (PVC, Latex, Acrylacetate, TiO2, etc.)

- Pulp and paper industry (spent sulfate and sulfite solutions, WATER solutions SO2, deodorization during condensation)

- Cleaning of municipal and chemical wastewater (fermented silt, thermal sterilization, wastewater and discharged water)

- Mining (Aluminum lyes, bauxite suspensions, magnesium oxides)

- Steel, gas processing and coke plants (Benzol, washing oils, SOLUTION NH3, irrigation capacitors)

- Textile industry (Heat recovery of dyes and washing liquids)Sugar and food industry, brewing (press water, raw juice, sewage, vegetable oil, alcohol, potato, cereal sebeil or corn pastes)

Fluid movement scheme in spiral heat exchanger

Assign. Spiral heat exchangers are used in alcohol, food, pharmaceutical, oil, chemical, utilities and other industries where high-efficiency heat exchange is required.

In alcohol plants, the use of spiral heat exchangers allows to drastically reduce the amount of water consumed.

You can use liquids that contain up to 20% solid impurities (sugary wort, brace), as well as oncoming streams of gas-liquid and gas-gas. Horizontal spiral heat exchangers are used for heat exchange between two liquids.

Vertical spiral heat exchangers are used for heat exchange between condensing steam and liquid; such heat exchangers are used as capacitors and steam heaters for liquid.

- Cooling;

- Heating;

- Heat recovery;

- Condensation;

- Evaporation;

- Thermosifon;

- The reboyler.