Processing of post-alcohol bards at the enterprises of the alcohol industry (DDGS, DDG)

BTS ENGINEERING offers innovative technical solutions in the field of post-alcohol stillage processing

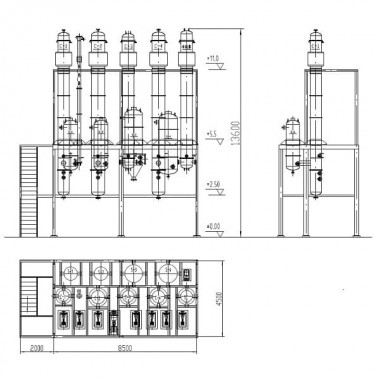

Stillage drying, fluidized bed drying, DDGS drying

The proposed technology contains the following elements of novelty:

- use of membrane technology for thickening of separation products distillery stillage;

- use of membrane filtration technology for technological water and their return to the production cycle;

- automatic control and process control system

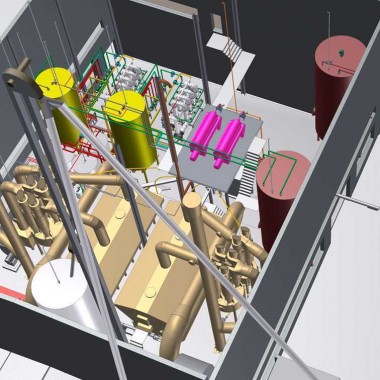

Distillery stillage processing process

Distillery stillage contains about 6 ... 9% of dry substances, in depending on the quality of grain supplied to the technology and technological methods used at the enterprise at different stages alcohol production. In distillery stillage are included in composition of grain raw materials: crude protein, nitrogen-free extractive substances, fat, fiber, ash, vitamins and trace elements.

It is not always rational to use distillery stillage in liquid form due to storage problems - the proteins that make up it are already after a short time they begin to decompose, and also economically not its long-distance transportation is beneficial.

In order to fully utilize the distillery stillage as highly nutritious feed, its multistage processing is offered with the receipt of a line of commercial products used as feed for farm animals and additives to concentrated feed.

In addition, an environmental problem is being solved in parallel - protection soils, surface and ground waters from pollution by products decay of the bard, which occurs with the standard, today, method of disposal of post-alcohol stillage - keeping it in the storage room.

The proposed recycling technology is as follows.

Distillery stillage from the beer column is cooled in recuperative heat exchangers heating technological media, then enters to a decanter (horizontal centrifuge), where it is divided into solid fraction - cake (31 ... 33% of absolutely dry substances, then - ASV) and liquid - centrate (4 ... 4.5% ASV).

The cake storage time is 8-12 hours, so drying is more efficient for getting DDG. The centrate is thickened in the microfiltration unit to obtaining another marketable product - concentrate (20 ... 23% DIA). The concentrate can be used for livestock feed as independent marketable product, but with the aim of improving nutritional qualities of BVK, the concentrate is mixed with cake and dried.

Waste from concentrate thickening - permeate (1.0 ... 1.5% absolutely dry substances), mixed with luther water, subsequently, after correction of physical and chemical composition and pH, returns to the main production by means of a nanofiltration plant as permeate, where used to prepare the batch.

Concentrate after nanomembrane installation, in reverse mode, mixes with the centrate and goes for separation and thickening in microfiltration plant, where bound after pH correction substances of organic and inorganic origin are derived from main stream together with centrate concentrate.

In full, the proposed recycling technology of post-alcohol stillage was launched at the bioethanol plant JSC "BIOFUTURE" (m. Silute, Republic of Lithuania)

Table 1. Balance of raw materials, products and waste 3000 dal

| Raw materials /products | Unit meas. | Costs | Notes | |||

| hourly | daily | annual (330 days) | specific for 1 dal | |||

| Distillery stillage | m3 | 16.7 | 400.8 | 132264 | 0.1336 | |

| Distillery cake cake | t | 1.55 | 37,221 | 12282.9168 | 0.01241 | possible marketable product |

| Fugate stillage distillery | t | 15.07 | 361,575 | 119319.7632 | 0.12053 | |

| Product yield (dry stillage) | t | 1.06 | 25.3779 | 8374,716 | 0.00846 | possible marketable product |

Table 2. Balance of energy resources

| Resource type | Unit meas. | Costs | |||

| hourly | daily | annual | specific for 1 dal | ||

| Electricity | kWh | 130 | 3120 | 1029600 | 1.04 |

| Artesian water (cooling hydraulic seals, periodic flushing) | m3 | 0.05 | 1,2 | 396 | 0.0004 |

| Heat energy for dryer | Gcal | 2.8819 | 69.17 | 22824.65 | 0.0231 |