Barrel pumps - TR

Drum chemical pumps are used for pumping acids and alkalis, neutral, corrosive liquids from barrels and eurocubes.

Each pump includes a submersible pump and motor, which are not immersed in liquid during operation. The pump section can be 900 or 1200 mm long.

The main competitive advantages of the TR series pumps are the low price and the protection class of the motors IP 54 (protection against dust and splashes) by default. Competitors have IP 54 motors more expensive.

Drum pumps (drum pumps) are small-sized and especially convenient for pumping solvents, liquids from containers, including aggressive ones. Such a pump, immersed in liquid, does not need an internal mechanical seal (which most often wears out) and its design ensures that any liquid leakage, even accidental, will be collected in the container.

Barrel pump TR can be supplied with an electric or pneumatic motor. The open rotor ensures continuous pumping of clean corrosive liquids with a visible viscosity of up to 600 cP.

Distinctive featureof our barrel pumps is that they are designed, in contrast to similar pumps, in a sealless scheme (without mechanical seal), which significantly increases their reliability.

|

|

|

- Execution options: polypropylene (PP), polyvinylidene fluoride (PVDF), stainless steel AISI 316;

- Interchangeability: electric motor or pneumatic motor;

- Work with corrosive liquids;

- Variable capacity (models with pneumatic motor);

- Immersion pipe length: 900 mm or 1200 mm;

- Lack of internal seals;

- Viscosity up to 600 cps;

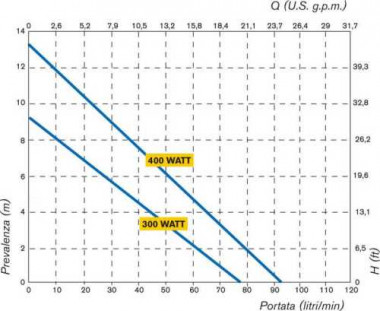

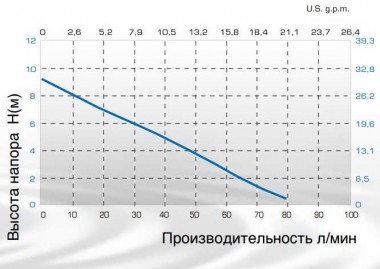

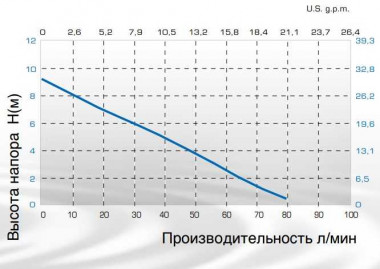

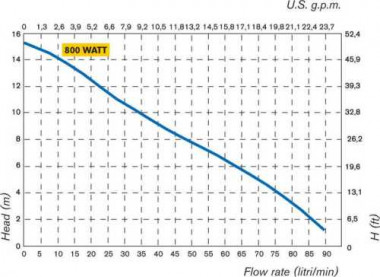

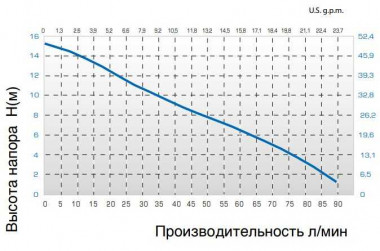

- Productivity up to 90 l /min;

- Portable, with the possibility of easy dismantling;

- Price quality;

External view and internal structure of Debem TR barrel pumps

The left side of the image shows two versions of the appearance of TR drum pumps (with an electric motor and with an air motor). The inside of the pump is shown on the right.

Barrel transfer pumps consist of a submersible tube, at the end of which there is an impeller attached to a drive shaft connected to the pump by means of a convenient clamping ring, while transmission is carried out by means of a cardan coupling.

Explanation of the designation of Debem TR pumps

Here is an example of a pump designation:TR PH-1200-EL

- TR - a series of pumps

- P - casing of the pumping part made of polypropylene (F - from PTFE, A - from stainless steel AISI 316).

- H - hastelloy pump shaft (S - stainless steel)

- 1200 - immersion length in mm (can also be 900 mm).

- EL - with electric motor (PN - with pneumatic motor)

Operating conditions

The temperature of the pumped liquid must be between 0 and +65 ° C for the polypropylene version or up to + 95 ° C for the PVDF or stainless steel version. Permissible fluid viscosity up to 600 cps.

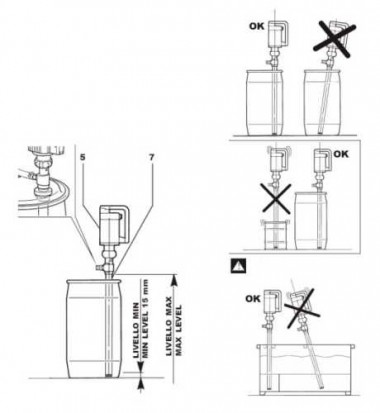

Installation example /drum pumps

|

|

|

Barrel pump accessories