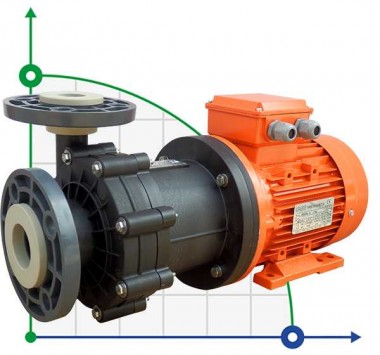

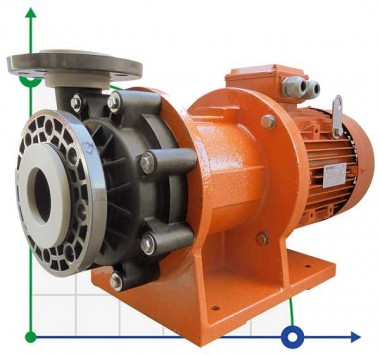

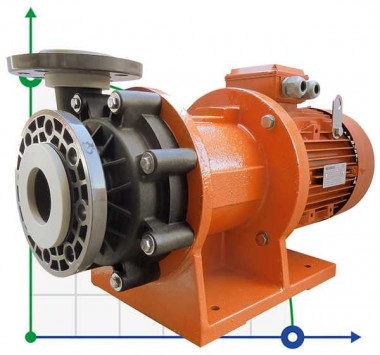

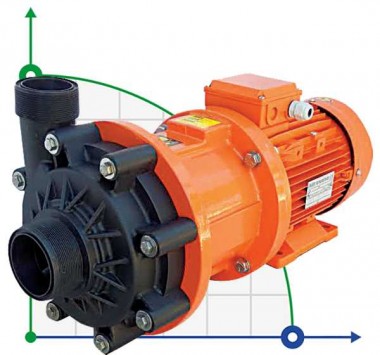

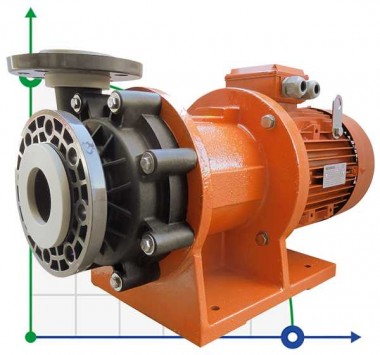

ADM Magnetic Drive Pumps

Features

Magetic drive centrifugal pumps series ADM PP /PVDF are made of thermoplastic materials (Polypropylene and PVDF) and are suitable for high corrosive liquids.

Thanks to the innovative mag drive system, pumps models ADM PP/PVDF reduce the risks of losses and the maintenance costs. The transmission of the motion occurs through magnetic joints without using mechanical seals. This guarantees the maximum safety and efficiency.

The pumped liquid has to be clean and without solids in suspension.

Technical Data

- Materials in contact with the liquid: casing and impeller PP/PVDF

- High torque magnetic coupling NeFeBo standard

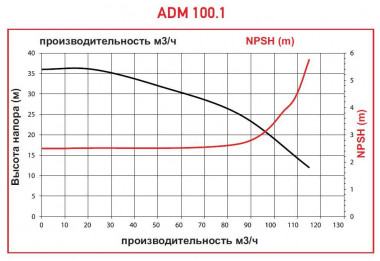

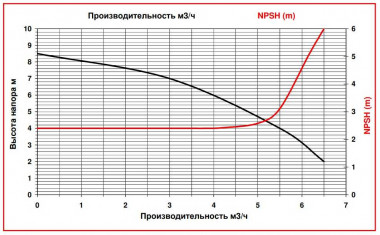

- Flow up to 130 m3/h pressure up to 48 mlc

- Max temperature: PP 60°C – PVDF 90°C

- Max viscosity: 200 cSt

- Pressure rating NP 5 at 20°C

- Upon request the pump can be supplied with flange PN 10, ANSI 150, JIS

Installation

ADM Magnetic drive Centrifugal pumps should be installed with the shaſt positioned horizontally in a positive suction head arrangement. Suitable devices should be fitted to prevent dry running and the formation of a vortex and possible air suction. ADM Magnetic drive centrifugal pumps should only operate whilst filled. Running dry or with bubbles can cause damage.

Application sectors

Chemical Industry, Galvanic & electronic Industry, Water Treatment Industry, Automotive

Design of magnetic drive centrifugal pumps

Magnetic drive centrifugal pumps have a particular seal-less design that is suitable to pump corrosive and dangerous liquids thanks to the high chemical resistance and absence of leakage and emissions. The structure is really simple so that the pump requires low maintenance cost with consequent economy in terms of repairing and spare part costs during the pump life.

The external magnet is directly connected to the motor shaſt and it transmits the torque to the internal magnet. The magnetic field created produces a rotation without physical contact between the parts so the impeller spins and moves the fluid. The rear casing is placed between the two magnet joints and it hermetically closes the hydraulic part from the motor.

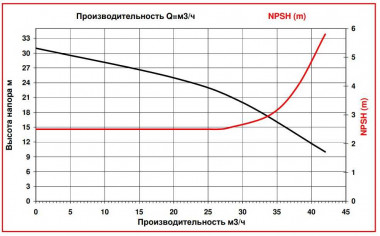

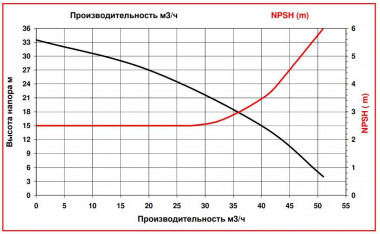

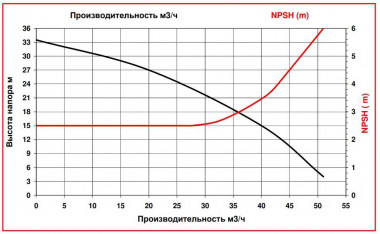

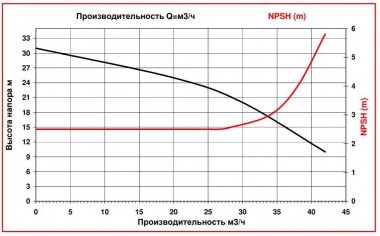

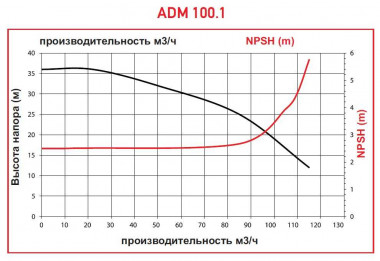

Pump Models

Performances